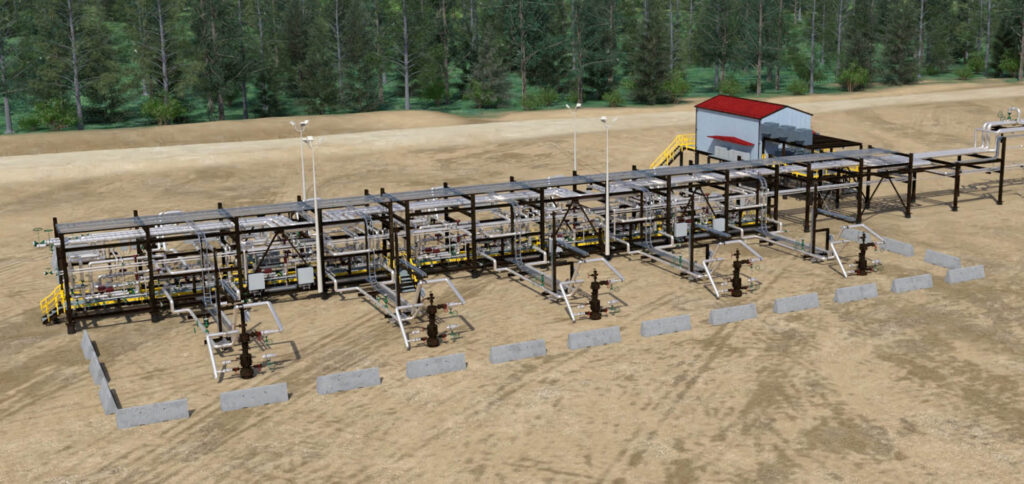

Equinox Engineering delivers an innovative approach to modularization for SAGD Well Pads.

This schedule driven project was delivered on-time and on budget, utilizing a highly modularized and innovative approach. Pipe rack modules minimized the high cost of site work and were fully completed at the fabrication yard and shipped to site. Innovation in design was achieved through discipline interaction and close communication with the client and operations, resulting in a cost effective and fit for purpose approach. Operational accessibility and layout were keys to success.

Located southeast of Fort McMurray (Canada), this Well Pad project feeds an existing 20,000 barrel per day Central Processing Facility. As part of ongoing development, additional surface facilities were added to the existing field and consisted of 5 new well pairs, associated pipe rack modules and a new MCC building.

Originally conceived as a stand-alone pad, steps were taken to incorporate the new pad design into the existing pad design, to minimize infrastructure costs. The new pad was designed to receive HP steam from the existing pad for injection and to gather produced fluids (bitumen, gas and water) from producer wells for transportation to the Central Processing Facility via existing infrastructure.

Get in touch today to learn more about how Equinox’s modularization approach could benefit your projects.