Equinox successfully executed the FEED and is currently executing the Detail Design for the Lift Gas Facility. This 30 MMscfd Lift Gas Facility is a brownfield expansion to an existing 240 MMscfd processing facility.

The intent of the facility is to both free up processing capacity at the existing Gas Plant (in northern British Columbia) and to provide low cost lift gas to increase production in the condensate rich wells.

An additional cashflow benefit is that the existing gas processing facility will have an increased capability of handling a higher liquids yield. This generates a significant cashflow increase through processing the liquids rich gas.

Project Execution Highlights

To capitalize on the cashflow opportunity – Equinox accelerated the project schedule by two months. In addition, Equinox reduced overall project costs by completing early work scope ahead of schedule to meet plant shutdown, modularizing valve platforms, purchasing all major equipment early, and reducing vendor scope, and completing many detail engineering tasks and deliverables within the schedule and budget of the FEED study.

Facility Highlights

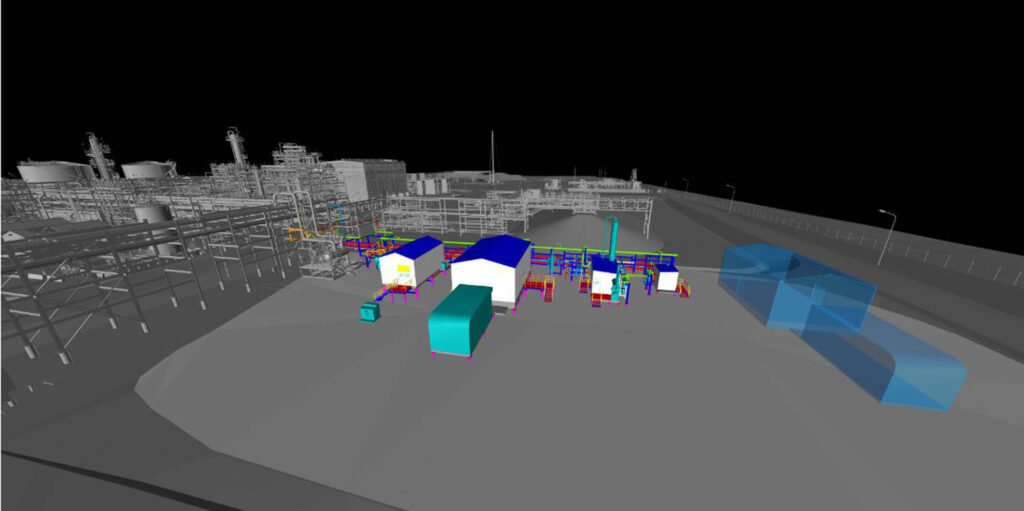

The brownfield Lift Gas Facility compresses and dehydrates a stream of gas downstream of the inlet slug catcher. A 2-stage 2750 hp reciprocating compressor will be installed in order to overcome wellhead operating pressure. Dehydration will remove saturated water from the gas lift stream to eliminate/minimize freezing.

The compressed and dehydrated gas stream will utilize existing frac water pipelines to be redistributed back to the wellheads. Any excess gas not required for gas lift will be commingled with sales gas.

Major equipment includes inlet filter separator; lift gas compressor package; glycol dehydration package; lube oil coalescing filter; VRU compressor package; MCC skid; and LV transformer. Provisions are being made for a future compressor.