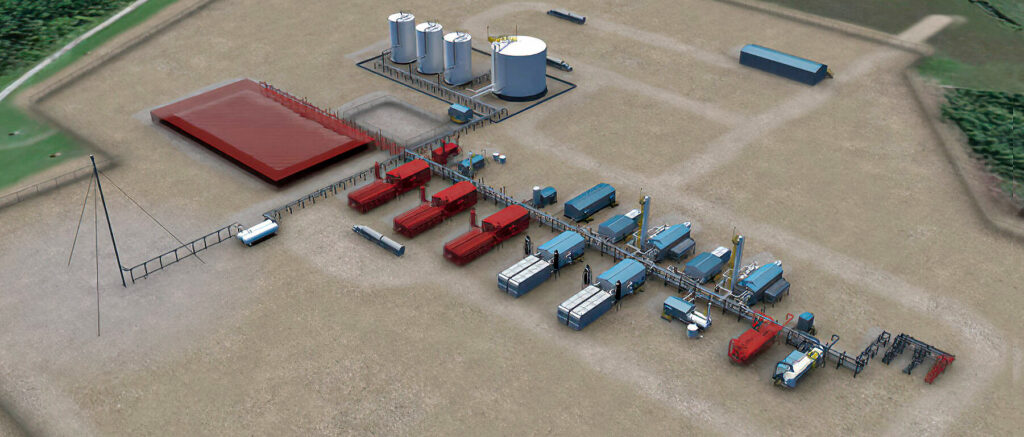

Pouce Coupe Sour Gas Plant (60 MMscfd)

Equinox Projects Pouce Coupe Sour Gas Plant (60 MMscfd) Project Summary: A modular facility designed for ease of transportation and remote assembly. 60 MMscfd capability to handle inlet process gas containing 1.5% H2S and 3.0% CO2. The process trains contain, line heating, inlet separation/ pipeline slug catcher, amine sweetening, refrigeration, liquid fractionation and stabilization, acid …