Moomba CCS to cut SA emissions by 7%

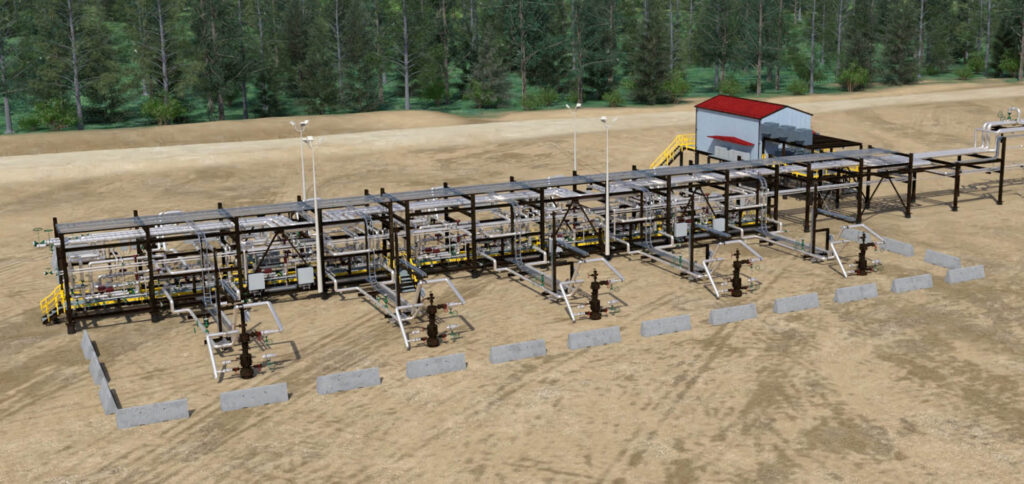

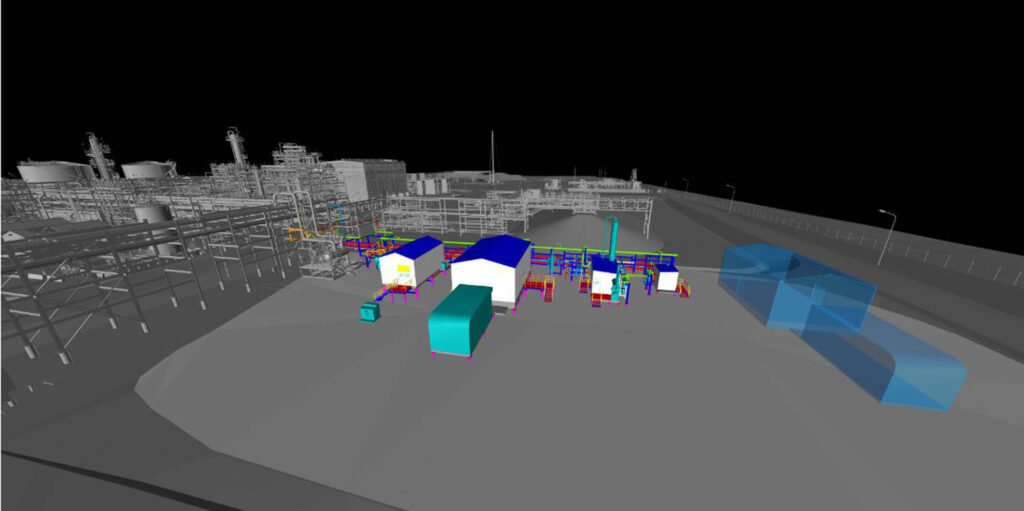

Equinox is proud to deliver Detail Design services for the Santos Moomba Carbon Capture project. Dept. of Energy & Mining (South Australia) advises that this represents a cut of 7% to all South Australia emissions. The CCS project will permanently store 1.7 million tonnes of CO2 per year. Read more.